ASSEMBLY OF PCB USING SMT, THT, THR

SMT, THT, CABLE

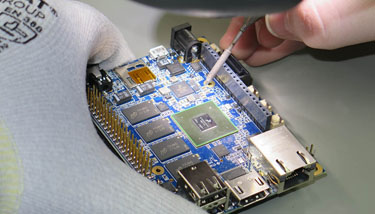

Surface Mount Technology (SMT)

- prompt data-to-production cycle, expert evaluation

- components from our stock

- six independent lines

- throughput 100.000 CPH, from 01005, µBGA

- Automatic Solder Paste Inspection and assembled components (3D SPI, 3D AOI)

- Oxygen free soldering, Re-flow or Vapor phase ovens

- Lead-free RoHS or Lead or glue assembly process

- from prototypes to series production

- user friendly initial costs

Through Hole Technology (THT)

- in-line dual wave soldering for Lead or Lead-free technology

- selective soldering under Nitrogen, Lead or Lead-free

- basic THT components from our stock

- hot bar soldering

- conformal coating

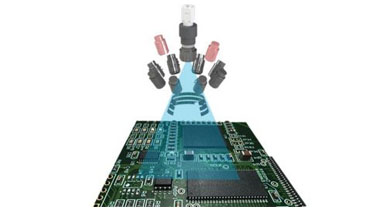

3D Automatic Optical Inspection (AOI)

- 10µ horizontal resolution

- 2µ vertical resolution

- 8 projector angles, no shadow locations, high resolution camera

- coplanarity check

- component orientation, OCR, lead solder inspection

- from 01005, high throughput, …

- X-Ray 2D and 3D (CT)

Our stock of SMT and THT components

available in packing quantities, suitable for machine assembly, waste tolerance is our problem, project related components – on demand

Loading...

Loading...